1. Uvod

This manual provides essential information for the safe and effective operation, setup, and maintenance of your Reboot RBM2500 PRO 8-in-1 Multi-Process Welder. Please read this manual thoroughly before operating the equipment. Retain this manual for future reference.

2. Sigurnosne informacije

Welding operations can be hazardous. Always follow safety precautions to prevent injury or damage. Failure to comply with safety instructions may result in serious injury or death.

- Zaštita očiju: Always wear a welding helmet with appropriate shade lenses to protect your eyes from arc rays.

- Zaštita tijela: Wear flame-resistant clothing, gloves, and safety shoes to protect against sparks, heat, and electric shock.

- ventilacija: Ensure adequate ventilation to remove welding fumes and gases from the work area.

- električna sigurnost: Never operate the welder in wet conditions. Ensure proper grounding and inspect cables for damage before each use.

- Prevencija požara: Držite zapaljive materijale dalje od područja zavarivanja. Imajte aparat za gašenje požara pri ruci.

- plinske boce: Handle gas cylinders with care. Secure them to prevent falling.

3. Proizvod je gotovview

The Reboot RBM2500 PRO is a versatile 8-in-1 multi-process welding machine designed for various welding applications. It supports Gas MIG, Flux Core, Lift TIG, Stick (MMA), Spot welding, and Spool Gun operations. This unit offers dual voltage flexibility (120V/240V) and a maximum output of 250A.

Slika 3.1: Reboot RBM2500 PRO Multi-Process Welder and included accessories. This image displays the main welding unit, MIG torch, ground clamp, držač elektroda i razni potrošni materijal.

3.1 Ključne karakteristike

- Multi-Process Capability: MIG (Gas/Flux Core), Lift TIG, Stick (MMA), Spot, Spool Gun.

- Dual Voltage: Operates on 120V or 240V power input.

- Visoki izlaz: Do 250 Amps for welding various materials and thicknesses.

- Digitalni prikaz: Large LED display for accurate data and easy readability.

- Included Electrode Holder: A 300AMP heavy-duty copper electrode holder is included for robust ARC/Stick welding performance.

Slika 3.2: The large LED display of the RBM2500 PRO, showing welding parameters and settings for different processes.

3.2 Uključene komponente

- Reboot RBM2500 PRO Welder Unit

- MIG baklja

- Prizemlje Clamp

- 300AMP Heavy Duty Copper Electrode Holder

- Power Adapter (for 120V/240V)

- Consumables (e.g., contact tips, nozzles)

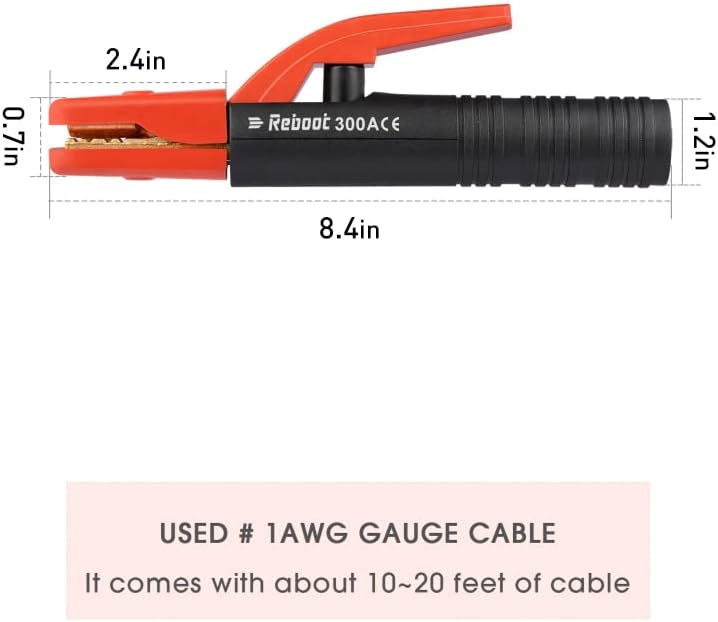

Slika 3.3: The included Reboot 300ACE heavy-duty copper electrode holder, designed for reliable ARC/Stick welding.

4. Podešavanje

Proper setup is crucial for safe and efficient welding. Follow these steps carefully.

4.1 Priključak za napajanje

- Provjerite je li prekidač za napajanje aparata za zavarivanje u položaju ISKLJUČENO.

- Determine the appropriate voltage for your power source (120V or 240V).

- Connect the power cord to the welder and then to a suitable grounded electrical outlet. Use the provided adapter if switching between 120V and 240V.

- Verify that the circuit breaker or fuse rating is sufficient for the welder's maximum current draw.

4.2 Prizemni Clamp Veza

Spojiti uzemljenje clamp cable to the appropriate terminal on the welder. Securely attach the ground clamp to the workpiece or a clean, bare metal portion of the welding table. A good ground connection is essential for arc stability and safety.

4.3 Welding Torch/Holder Connection

- MIG baklja: Connect the MIG torch cable to the front panel connector. Ensure it is securely tightened.

- Electrode Holder (Stick/MMA): Connect the electrode holder cable to the positive (+) terminal for most applications, or negative (-) depending on electrode type and desired penetration.

- TIG gorionik: Connect the TIG torch to the appropriate connector. For Lift TIG, a gas connection may also be required if using shielding gas.

Slika 4.1: Detail of the electrode holder connection, illustrating the use of an Allen wrench for efficient and secure cable attachment.

4.4 Gas Connection (for Gas MIG/TIG)

If performing Gas MIG or TIG welding, connect the gas hose from your shielding gas cylinder regulator to the gas inlet on the rear of the welder. Ensure all connections are tight and leak-free. Set the gas flow rate according to your welding process and material.

5. Načini rada

The RBM2500 PRO offers multiple welding processes. Select the desired mode using the control panel and adjust parameters accordingly.

Slika 5.1: Visual representation of the 8-in-1 multi-process capabilities of the RBM2500 PRO welder, including MIG, MMA, Spot, Flux Core, Spool Gun, and Lift TIG.

5.1 MIG Welding (Gas MIG / Flux Core)

MIG welding uses a continuously fed wire electrode and, for Gas MIG, an external shielding gas. Flux Core welding uses a self-shielding wire that does not require external gas.

- Install the appropriate wire spool (solid wire for Gas MIG, flux-cored wire for Flux Core).

- Feed the wire through the torch liner and out the contact tip.

- Select 'MIG' mode on the welder.

- Podesite voltage i brzina dodavanja žice u skladu s debljinom materijala i vrstom žice.

- For Gas MIG, ensure shielding gas is connected and flowing.

5.2 Zavarivanje podizanjem TIG-a

Lift TIG welding provides precise control and high-quality welds, typically used for thinner materials.

- Install a tungsten electrode into the TIG torch.

- Connect shielding gas (typically Argon) and set the flow rate.

- Select 'Lift TIG' mode.

- Podesite amperage based on material thickness.

- Initiate the arc by gently touching the tungsten to the workpiece and lifting slightly.

5.3 Stick Welding (MMA/ARC)

Stick welding uses a consumable electrode coated with flux. This process is versatile and suitable for outdoor use and thicker materials.

- Insert the desired electrode into the 300AMP electrode holder.

- Select 'Stick' or 'MMA' mode.

- Podesite amperage according to the electrode type and diameter, and material thickness.

- Strike the arc by lightly scratching or tapping the electrode on the workpiece.

Slika 5.2: The robust jaw grip of the 300AMP electrode holder, ensuring secure electrode retention during Stick welding operations.

5.4 Spot Welding

Spot welding is used for joining overlapping metal sheets at specific points.

- Select 'Spot' mode.

- Adjust the spot welding time and power settings.

- Position the MIG torch over the desired spot on the overlapping sheets.

- Initiate the weld.

5.5 Spool Gun Welding

The spool gun is typically used for welding softer wires like aluminum, as it minimizes wire feeding issues.

- Connect the spool gun to the designated port on the welder.

- Load the wire spool into the spool gun.

- Select 'Spool Gun' mode.

- Adjust welding parameters as needed for the specific wire and material.

6. Održavanje

Redovno održavanje osigurava dugotrajnost i optimalne performanse vašeg aparata za zavarivanje.

- čišćenje: Regularly clean the welder's exterior and ventilation openings to prevent dust and debris buildup. Use compressed air to clear internal components periodically.

- Inspekcija kablova: Inspect all welding cables, power cords, and gas hoses for cuts, abrasions, or loose connections before each use. Replace damaged components immediately.

- Torch/Holder Maintenance: Clean MIG torch liners, replace worn contact tips and nozzles. Ensure the electrode holder jaws are clean and provide a strong grip.

- Dodavač žice: Keep the wire feeder mechanism clean and free of debris. Check drive rolls for wear and adjust tension as needed.

7. Otkrivanje problema

Ovaj odjeljak se bavi uobičajenim problemima na koje možete naići. Za probleme koji nisu ovdje navedeni, obratite se korisničkoj podršci.

| Problem | Mogući uzrok | Rješenje |

|---|---|---|

| No Arc | No power, poor ground, incorrect settings, faulty cable. | Check power connection, ensure good ground, verify settings, inspect cables. |

| Loš kvalitet zavarivanja | Incorrect parameters, contaminated material, improper technique, insufficient gas. | Podesite voltage/amperage/wire speed, clean workpiece, review technique, check gas flow. |

| Problemi s dovodom žice (MIG) | Incorrect drive roll tension, clogged liner, wrong contact tip, bent wire. | Adjust drive roll tension, clean/replace liner, use correct contact tip, check wire spool. |

| Pregrijavanje | Exceeding duty cycle, blocked ventilation. | Allow welder to cool, ensure clear ventilation. |

8. Specifikacije

| Feature | Detalj |

|---|---|

| Model | RBM2500 PRO |

| Ulazni voltage | 120V / 240V (Dual Voltage) |

| Maksimalna izlazna struja | 250 Amps |

| Procesi zavarivanja | Gas MIG, Flux Core, Lift TIG, Stick (MMA), Spot, Spool Gun |

| Electrode Holder Capacity | 1/4 ~ 7/8 inch (with 300AMP držač) |

| ASIN | B0FBRLC7P9 |

| Datum prve dostupnosti | 13. maja 2025 |

Slika 8.1: Dimensions of the 300AMP electrode holder, indicating its length, width, height, and jaw opening.

Slika 8.2: The large 300-AMP electrode holder jaw, capable of securely holding electrodes from 1/4 to 7/8 inches.

9. Garancija i podrška

For warranty information, technical support, or service inquiries, please contact Reboot customer service. Refer to your purchase documentation for specific warranty terms and contact details.

Reboot Customer Support: Please visit the official Reboot webweb-mjesto ili pogledajte kontakt informacije koje se nalaze na pakovanju vašeg proizvoda.